ECAD Interface

SolariaPCB includes an interface with ECAD by importing ODB++ files. All components, layer definition, traces, vias and board shape are imported.

Click the figures to enlarge

Viewing the PCB

The View Entities dialog allows you to view each entity on the board interactively.

Click the figures to enlarge

Defining what you see

You can display components by their type

You can also look at each layer of the board

Click the figures to enlarge

PCB layer definition

Layer definition

Layers are completely defined when an ECAD file is imported. Layers can be manually added and edited as well.

Click the figure to enlarge

Add/Edit Vias

Maually adding Vias to the board

In addition to vias importd from your ECAD tool, you can manually add a field of vias under a component to help get that heat to the power and ground planes.

Click the figure to enlarge

Adding Stiffeners

Adding a Stiffener to the board surface

A Stiffener is a structural member attached to the board to make it more regid. But because it is typically made of aluminum, it provides a heat transfer path.

Click the figure to enlarge

Add Surface Heat

Adding Surface Heat loads to a layer in the board

In addition to components dissipating heat, there may be other devices that dissipate heat on the board. You can simulate them by simply adding an area of heat load to the board. If it is a burried resistor inside the board, you can simulate that too by just selecting the layer in the board it is on. Because SolariaPCB creates a full three-dimensional board, you will see that the temperatures inside the board are hotter than the outside, something nearly impossible to measure in a test.

Click the figure to enlarge

Adding a Thermal Contact

Define areas of thermal contact with the chassis system level model

You can define an area of thermal contact between the board and the electronics chassis. You can define the edge temperature for the contact or if you don't IntelliMesh Slave surfaces are generated. IntelliMesh allows you to thermally connect the contact area to a chassis level model that have a very different mesh.

Click the figure to enlarge

Simulating Air Flow

Represent air flow across the board

Solaria does not solve for air flow but can simulate the effects of air flowing over the board using convection elements from local air nodes to the exposed surfaces of the board along with Flow elements to account for the temperature change of the air.

Click the figure to enlarge

Defining what components are Active

Easily define what components are to be included in the thermal model

When an ECAD database is imported, connectors, test points, capacitors, resistors and many other types of components are imported. Typically, Integrated Circuits (ICs) are the main area of concern. So in the Active Component dialog, you can check ICs then hit the Set Active button to set only ICs as active. They will then be the only components thermally represented in the Solaria thermal model. Every component on the board will have at least a local board surface temperature. This will allow you to ensure devices like capacitors do not exceed their maximum allowable temperature.

Click the figure to enlarge

Component Geometry

Component Geometry

Show is the dialog for defining the geometry of a leaded component. SolariaPCB comes with a component library which contains over 400 components. The geometry of each was derived from JEDEC.org.

Click to enlarge

Click the figure to enlarge

Component Thermal data

Component Thermal Data

You can define how the component is thermally represented. The power dissipated by the component can be defined in the Working library or at the Reference Designator level. Components can be represented by a simple Junction-to-Case resistance or a DELPHI representation. The thermal resistance from the compoennt case to the board is calculated by SolariaPCB from the data in the library.

Click the figure to enlarge

Map Components

Mapping Components

SolariaPCB comes with a component library which contains over 400 components. The data for each component was derived from JEDEC documents. It includes component geometry including lead/pad/solder ball information. In most cases it includes thermal information. Because there is no such thing as accurate thermal resistance data for a specific package type (due to the many construction and die variables) this data should be reviewed.

When an ODB++ file is imported, component outline, lead/pad/solder ball locations and at times, component height are imported. To make a thermal connection to the board, lead/pad/solder ball geometry and material are needed.

Go here for more information.

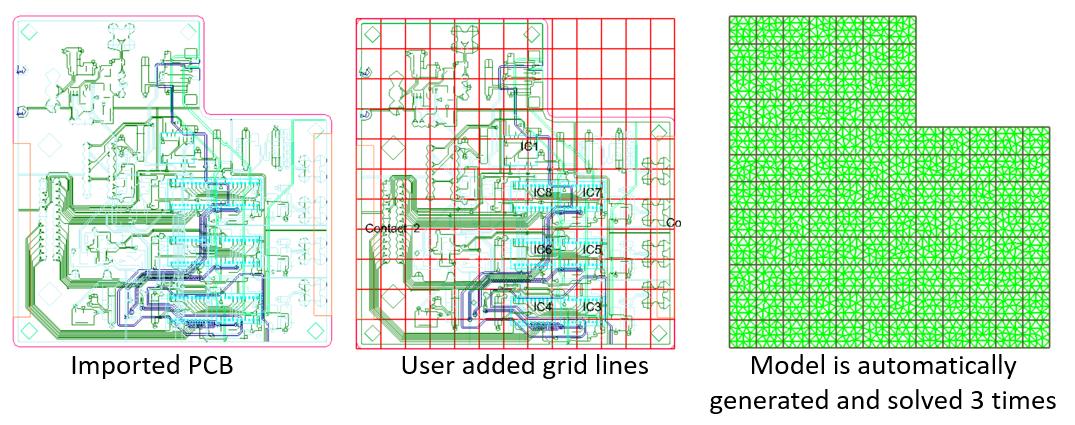

Trace Representation Layer 1

The board is first meshed exactly represnting the PCB outline, components, stiffeners, thermal contact areas, surface heat loads and other geometry. Traces and vias do not influence the mesh. The user can define a general mesh size constraint. After the board is meshed, for each metal layer, the traces crossing each triangle in the mesh is thermally represented by three resistors. This methodology gives an accurate trace representation yet solution times are in minutes. The left picture shows traces. The middle picture shows the thermal resistors that represent them. The right picture shows them overlaid.

Click the figure to enlarge

Trace Representation Layer 2

The left picture shows traces. The middle picture shows the thermal resistors that represent them. The right picture shows them overlaid.

Click the figure to enlarge

Via representation

Every via is thermally represented in the Solaria thermal model. When an ECAD database is imported, every via is imported. The diameter and the layers it is electrically attached to is imported. In the Settings dialog, the plating thickness and material is defined as well as whether the vias are filled or not. If they are then the fill material is defined. At the board mesh element level, thermal resistors are created between the layer nodes the via is electrically attached to.

Click the figure to enlarge

Component Temperatures

After solving the model, when you create a temperature color contour in Solaria, component Junction and Case temperatures are graphically represented. A tabular summary is also given for each board in the chassis model. You can save the data to a file to import into Excel or a report.

Click the figures to enlarge

PCB Effective Properties

For each cell, the thermal conductivity in the X, Y and Z directions is automatically calculated. Click on the above to get more information.

Calculate Board Voltages

Define Voltage sources and Current sinks on different layers on traces or planes and SolariaPCB will automatically calculate their voltages, calculate the power dissipation based on the voltage drops and include the heat in the thermal model. Watch the 15 minute demonstration video.

Even traces on different layers are electrically connected by the vias imported from the ODB++ file. Check out the 9 minute demonstration video.